Production Facilities

TECHNOLOGY WITH FACILITY

At our state-of-the-art manufacturing facility, we integrate cutting-edge technology with skilled craftsmanship to produce high-quality socks that meet the needs of both fashion and function. Our advanced machinery and automated systems ensure precision, consistency, and efficiency at every stage of production.

01. SETTING THE TONE

At the very beginning of our process, we focus on understanding your exact needs and preferences for your socks. Every client has a unique vision, and we make sure to capture that clearly before we start production. This involves discussing your design ideas in detail, the kind of patterns you want to see, and any specific styles you prefer. We also pay attention to the technical aspects, such as the type of machinery work required to achieve the desired finish and look.

02. Designing Your Socks

In this stage, we carefully finalize the patterns and designs that will define your socks. As experts in custom sock manufacturing, we transform your unique ideas into precise digital codes that our advanced knitting machines can easily interpret. This process ensures that every detail of your design is accurately captured and flawlessly produced. Our experienced design team takes care of everything—from converting your vision into machine-friendly codes to supervising the production process.

With their creativity and technical skills, we guarantee that your custom socks are crafted exactly as you imagined, with quality and precision in every stitch.

03. A Sample is ready

After finalizing the design and all required details, we move forward by preparing a sample for you. This sample is usually ready and dispatched within 7 days, ensuring a quick turnaround. If you are satisfied with the approved design, the process continues smoothly into full production.

We do not charge any production fees for standard samples, keeping it simple and cost-effective. However, in case you request a fully customized sample, additional charges may apply depending on the requirements.

04. Yarn Selection

After the sample is ready in the available shades The next step choice of the yarn for your socks. Matching the right shade is an Art, you need years of experience and right contact for this. We use best of the class yarns, no matter how expensive the are. As for yarn selection, we use the company’s knitting yarns that are 80% cotton and 20% mixed fabrics. This should be good for you considering that we are the best socks manufacturers India has.

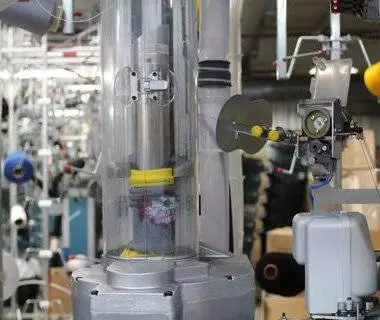

05. Knitting the Socks

Once all the previous steps are completed, we move forward to the actual production stage. At this point, the finalized designs are programmed, and every required procedure is carefully executed to maintain consistency and precision. Our goal is to deliver only the best-quality products, upholding our reputation as one of the leading wholesale sock manufacturers in India. To further assure you of our quality and reliability, we also provide a pre-production sample.

This sample allows you to review and confirm that the product matches your expectations before full-scale manufacturing begins.

06. Washing & Boarding

Once the socks is knitted and stitched and clever fabric expert chooses the best in class customised Softener and antibacterial chemicals, according to the need of the Socks and requirement of client. A strict protocol is followed according the rules and regulations of the country specific standards. And thereafter the socks finally reaches the boarding process. A final checking is also done here for any kind of holes or defects.

07. Inspection process

At this stage, our focus shifts to quality assurance, ensuring that every product meets the highest standards before moving further. The first level of inspection begins as soon as the initial production batch is completed. Our skilled team carefully examines each piece, checking for accuracy in design, consistency in stitching, and overall finish. Only after every item passes this step do we allow production to continue. Following this, a second round of inspection is carried out to double-check quality, guaranteeing that only flawless products move forward for final delivery.

08. Packing, Labeling of the socks

After boarding the next stage is check whether the socks are ironed and kept in good shape. They are then kept for shrinkage determination so that they are tidy and bright. The final product is the approved socks and these are paired and are finally inspected. Once they are proven to be the best quality, they are labeled, given hangtags, and are packed.

09. Shipping

This is the last stage of our production process. You can trust Yadav Products to deliver your order in the best way possible to wherever you are in the world.