Facilities & Scale

Facilities & Scale – Yadav Products

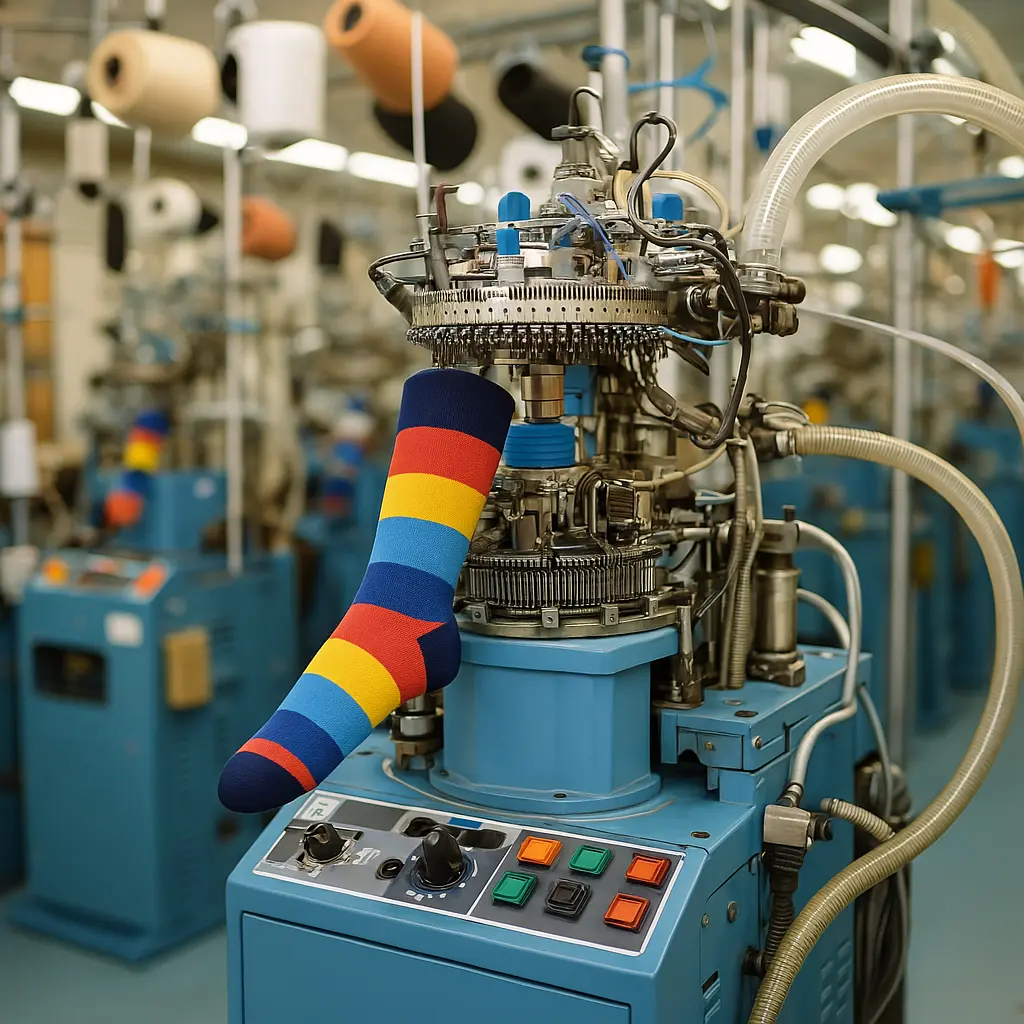

Yadav Productsis equipped with state-of-the-art manufacturing facilities, ensuring high-quality production of a wide range of socks. Our factory houses advanced knitting machines, automated stitching units, and modern finishing equipment, enabling efficient and precise manufacturing.

With a dedicated team of skilled technicians and quality inspectors, we maintain stringent quality control at every stage of production. Our large-scale production capacity allows us to fulfill bulk orders on time, catering to corporate, sports, school, and casual sock requirements.

From raw material selection to final packaging, every process is optimized for efficiency, consistency, and superior product standards. Yadav Products is committed to delivering socks that meet both quality and quantity demands reliably.

Yadav Products stands as a premier name in the socks manufacturing products, known for combining advanced technology, skilled craftsmanship, and large-scale production capabilities to deliver high-quality socks across various segments. With years of expertise and a strong focus on innovation, Yadav products has established itself as a reliable and trusted partner for businesses, schools, corporate clients, and retail customers seeking premium socks in bulk or customized design

Modern Manufacturing Infrastructure

Our facility also includes dedicated areas for yarn selection, color matching, pattern design, and quality inspection. Each stage of production is structured to optimize workflow and maintain smooth operations. By integrating modern machinery with skilled manpower, we are able to produce large volumes of socks without compromising on quality.

Skilled Workforce & Expert Supervision

Our workforce is also trained to handle customized requirements. Whether it is creating unique color combinations, special patterns, or incorporating corporate logos, our team ensures that client specifications are accurately translated into the finished product. The combination of skilled manpower and advanced machinery ensures that every order, large or small, receives the same level of attention and precision.

Large-Scale Production Capacity

We have optimized our production lines to achieve maximum output without compromising quality. By maintaining a balance between automated processes and skilled manual supervision, we ensure that every batch of socks meets our high standards. Our production capacity allows us to fulfill urgent orders while maintaining consistent quality across all products.

Research & Development

Quality Control & Assurance

Customization & Client Support

We also provide pre-production samples for approval before mass production begins. This ensures that clients can evaluate the design, material, and overall quality, reducing the risk of errors and enhancing satisfaction.